As a kind of mold steel used for plastic production, plastic mold steel is main material of plastic mold. The plastic mould steel has enhanced the development of industrial products to be advanced, diversified, individualized, and high value-added.

All countries in the world count the output of die tool steel into alloy tool steel, and its output accounts for about 70% to 80% of alloy tool steel.

If you want to learn more, please contact us.

HS 718 Plastic Die Steel

HS 718 Plastic Die Steel is modified 718 plastic die steel of pre hardened mirror surface, which has good hardenability, hardness uniformity and mirror polishing property.

Read More

HS 2738 Plastic Die Steel

HS 2738 is modified pre-hardened mirror plastic mold steel. It uses key technologies of alloy composition optimization and organization control.

Read More

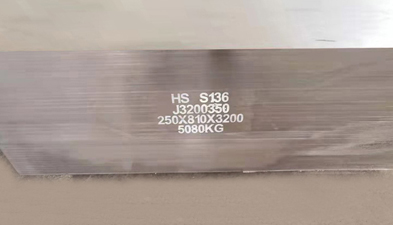

HS S136 Plastic Die Steel

HS S136 Plastic Die Steel has good corrosion resistance, high polishing performance and high wear resistance.

Read MoreFAQs of Plastic Die Steel

What is plastic die steel?

Plastic die steel is a kind of die steel used for plastic production, is main material of plastic mold.

What does ESR mean in die steel?

ESR (electroslag remelting) is a method of smelting. Comparing with electric furnace steel, electroslag steel has higher purity and better performance, and of course more expensive price.

What's the common problems and solutions of plastic die steel?

The common problems is: serious wear and tear and the mold is easy to scratch. The solution is to increase the hardness of the mold steel material, to use good steel, or to perform nitriding, carburizing and other metal infiltration on the mold surface to improve its surface wear resistance and prolong the service life.

Focus on manufacturing special steel cast and forged

components for more than 25 years.